We use traditional and modern forging techniques to build bike racks. We use anvils and hammers to shape hot iron and steel into sculptural forms to create functional public art that also can be used as a place to lock your bike!

We do a lot of our forging in a historic Erie Canal era blacksmith shop – short video tour of the forge…….

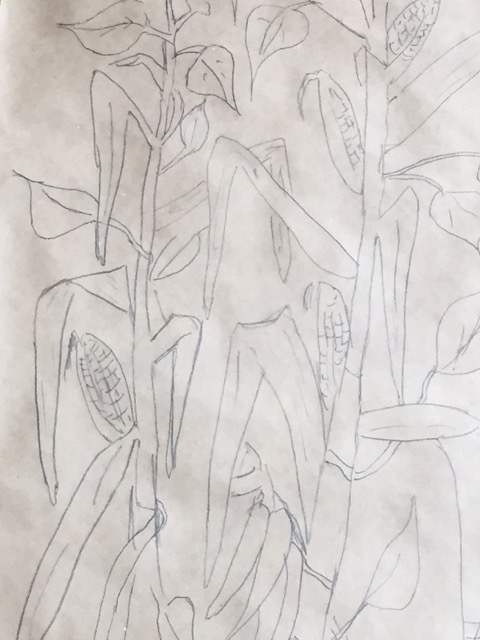

After a design has been chosen, we transfer the design to a full size drawing on paper. Here is the full size drawing (24″ x 36″) of the Three Sister Planting of corn, beans, and squash.

Then each component of the design is forged and compared to the drawing.

In this design based on the Three Sisters Planting, we have forged some large squash leaves on the left, some small bean leaves in the middle, and there are three green beans near the bottom. The twisted strands of steel in the upper right are the beginnings of an ear of corn.

This process of forging individual pieces can take up to two months to complete and then once all the pieces are ready, the final designs is fabricated using rivets, collars, or welding.

Steve is forging one of the many beans for the Three Sisters Planting design.

Steve is forging one of the many beans for the Three Sisters Planting design. Steve and Larry twisting round stock for ears of corn.

Steve and Larry twisting round stock for ears of corn.

Bryan and Larry working at the forge heating steel to make leaves.

The happy band of blacksmiths working on this project (L-R; Steve, Larry, Mike, Mark, Bryan, and Steve)

Own a piece of history

As part of this project, we are forging items to help our fundraising efforts. These small items will let many people be partners in our effort to increase the visual appeal of local communities and also encourage cycling.

Own a piece of history!!

We are forging small railroad spikes from railroad tie plates that were used on the old Westshore Railway between Oneida and Syracuse.

To start making these spikes, we needed to make a tool called a nail header so that we could start forging spikes. In blacksmithing, we often have to make several tools to start a project. Here is the nail header being made…..

We were given some railroad tie plates from the Westshore Railway which has now been turned into a great bike and walking trail called Oneida Rails Trails.

First job is to cut these plates into manageable pieces so that we can forge them into small railroad spikes. The best way to do this is by using an oxyacetylene torch

The cut plates now need to be forged into bars to ultimately make the smaller railroad spikes. This process can be performed using a hand hammer and some were forged this way.

Fortunately I recently traveled to the John C. Campbell School in North Carolina which is an amazing folk and craft school with an excellent blacksmith shop. While I was there I used their large Say-Mak power hammer to forge some more plates into bars. Using a large power hammer I could forge much faster (and louder) than by hand hammer.

After all that work, we can now start forging small railroad spikes from this hundred year old steel from the Westshore Railroad.

These hand forged railroad spikes will be available as keychains for our Kickstarter fundraising campaign that starts in August. Signup for updates by clicking on the logo on the right side of the screen.